These calculators are used to calculate rotary motion. If you need to calculate linear motion, please use the linear motion calculators.

$$ T = J \times \alpha $$

Torque = Inertia x Angular Acceleration

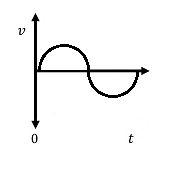

To size a stage properly the torque must be known. If torque is not known it must be calculated from this equation. The inertia is the total inertia of the customer payload plus the inertia of the moving components of the stage. If the acceleration component is not known it must be calculated. Calculators are provided under the Acceleration tab for estimating the acceleration of a system. Once the torque is determined, the duty cycle for all of the specific torques must be determined to calculate the RMS force, which is the average required torque. The Torque RMS tab provides the tools needed to determine the RMS Torque of a motion profile.

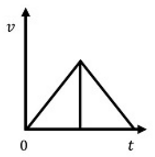

$$ \Large \alpha = \frac{4 \times \theta }{t^2} $$

$$ \Large \alpha = \frac{4 \times \theta }{t^2} $$