A customer approached H2W for a motorized solution for their warehouse sorting machine. The machine's core sorting mechanism incorporated a diverter that rotated approximately fifteen degrees. However, the original drive mechanism had been discontinued, leaving the customer needing a suitable drop-in replacement.

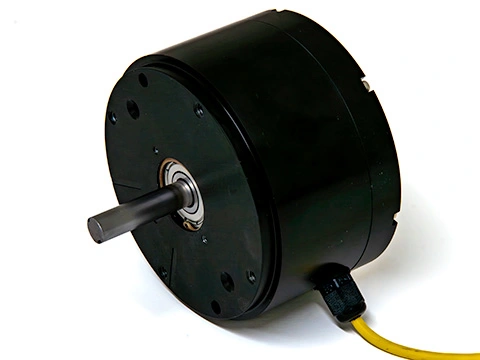

Given the limited rotational requirement and the torque necessary, an existing limited-angle torque motor emerged as the ideal solution for integration into the customer's machine. However, due to the customer’s need for a drop-in replacement, several customizations were necessary on the H2W standard part. Throughout the process, H2W's team of experts collaborated closely with the customer to understand their specific needs and requirements. They provided technical guidance and support, ensuring that the integration of the torque motor was executed without further complications.

Initially, H2W offered the customer a standard motor with a custom mounting hole configuration to ensure it met their torque and movement profile needs. This was integrated by the customer, where they could share the issues that needed to be addressed to make this motor a drop-in replacement. There were primarily three main issues that H2W had to address: a winding configuration that allowed for simple control, a custom connector and cable, and modifications to the torquer geometry to allow the part to mount to the customer’s assembly.

The simplicity of the motor's drive electronics called for a custom three-wire winding connection and cable. H2W leveraged the limited-angle torque motor's unique winding configuration to accommodate this requirement. By splitting the winding connections and adding the same cable and connector used by the previous motor, H2W enabled the customer to operate the torque motor effortlessly using their existing electronics. Paired with cutouts and additional pins made to the exterior design of the torque motor ensured seamless compatibility and allowed customers to implement the motor into their warehouse sorting machine.

As a result, the customer successfully restored the functionality of their warehouse sorting machine, enhancing its efficiency and reliability. The collaboration between H2W and the customer exemplifies the company's commitment to delivering tailored solutions that meet the unique challenges of various industries. The successful implementation of the limited-angle torque motor in the warehouse sorting machine is a testament to H2W's expertise in providing innovative motor solutions and its dedication to customer satisfaction.